THANK YOU

for purchasing the The Big Pair from CravenSpeed. This product is made from the highest grade materials, and is guaranteed to be free from defects.

You can buy our

CravenSpeed The Big Pair Chassis Brace for Third Gen MINIs here

You can buy a

Big Pair Chassis Brace for your car here

Parts Included:

-

Set of Big Pair

-

(6) M8 x 16mm Cap Head Screws w/ Washers (kit CS-AB621)

Tools Required:

-

Floor Jack

-

Jack Stands

-

Torque Wrench

-

T45 Torx Driver

-

6mm Hex Key Driver (kit CS-AB621)

-

Ratchet Wrench w/ 18mm Socket (kit CS-AA163)

The recommended torque spec is 26 ft/lbs. for the big brace (six M8 screws) and 97 ft/lbs for the small one (two M12 screws), which is based upon the recommended spec for the stock part it replaces.

NOTE:

Kit CS-AA163 (F56) consists of (1) large brace and (1) small brace. Kit CS-AF835 consists of (1) large brace only. Kit CS-AB621 (F54/F55/F60) consists of (2) large braces and some hardware that your particular installation may use.

-

Secure your MINI in a well-lit, level, and clean area. Lift one side of the MINI and place jack stands under the jack points. Slide underneath and locate the Small Pair (OEM sheet metal braces). The F56 and F57 will have (1) large brace and (1) small brace whereas the F54, F55, and F60 should have (2) large braces or at least mounting locations for two.

-

Remove the OEM fasteners from the factory braces and temporarily set them aside as you’ll be reusing them to install The Big Pair. Torx T45 for the large brace and an 18mm socket for the smaller one (F56/F57). For the F54/F55/F60 kit, you may or may not have two large factory sheet metal braces. The F60 we developed this kit from had only one large brace, but it did have threaded inserts in the body for an additional one. That is what the included M8 hardware is for.

-

Replace the factory braces with The Big Pair using the OEM hardware. Torque the M8 screws to 26 ft/lbs and the M12 screws to 97 ft/lbs.

-

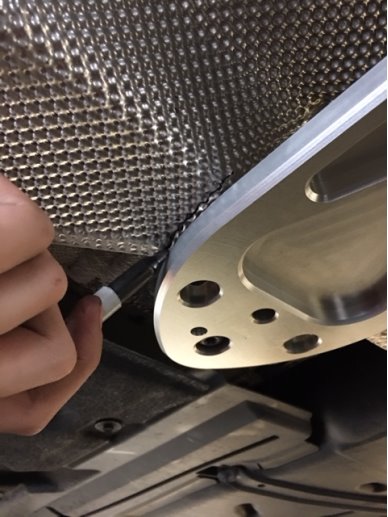

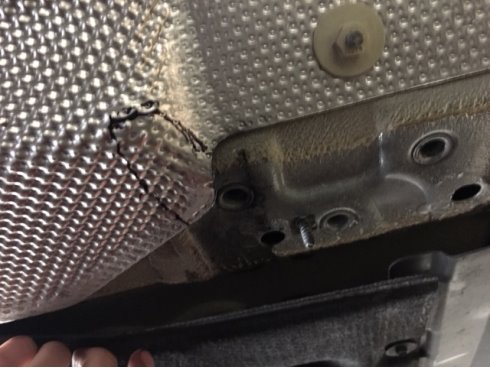

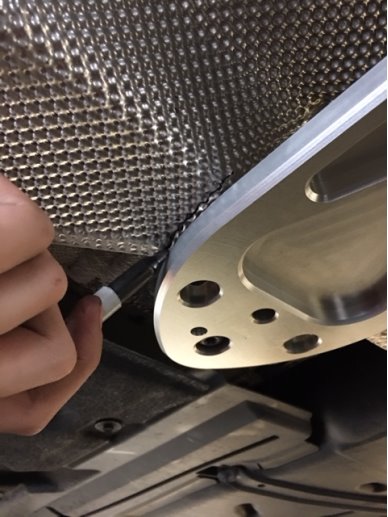

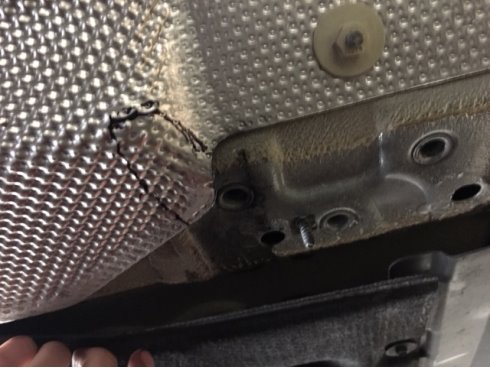

If any part of the heat shielding prevents you from mounting The Big Pair completely flat against the bottom of the vehicle (our F60 install reflected this), temporarily set the brace into place and use a marker pen to trace around the affected area. Use some tin snips to trim the heat shielding away and if necessary, tap the sharp edges down with a soft mallet.

-

Confirm all your hardware is properly torqued; M8 screws to 26 ft/lbs, M12 screws to 97 ft/lbs, clear away all random tools and safely lower your vehicle off of the jack stands.

-

Congratulations… your install is complete! Go motor hard!